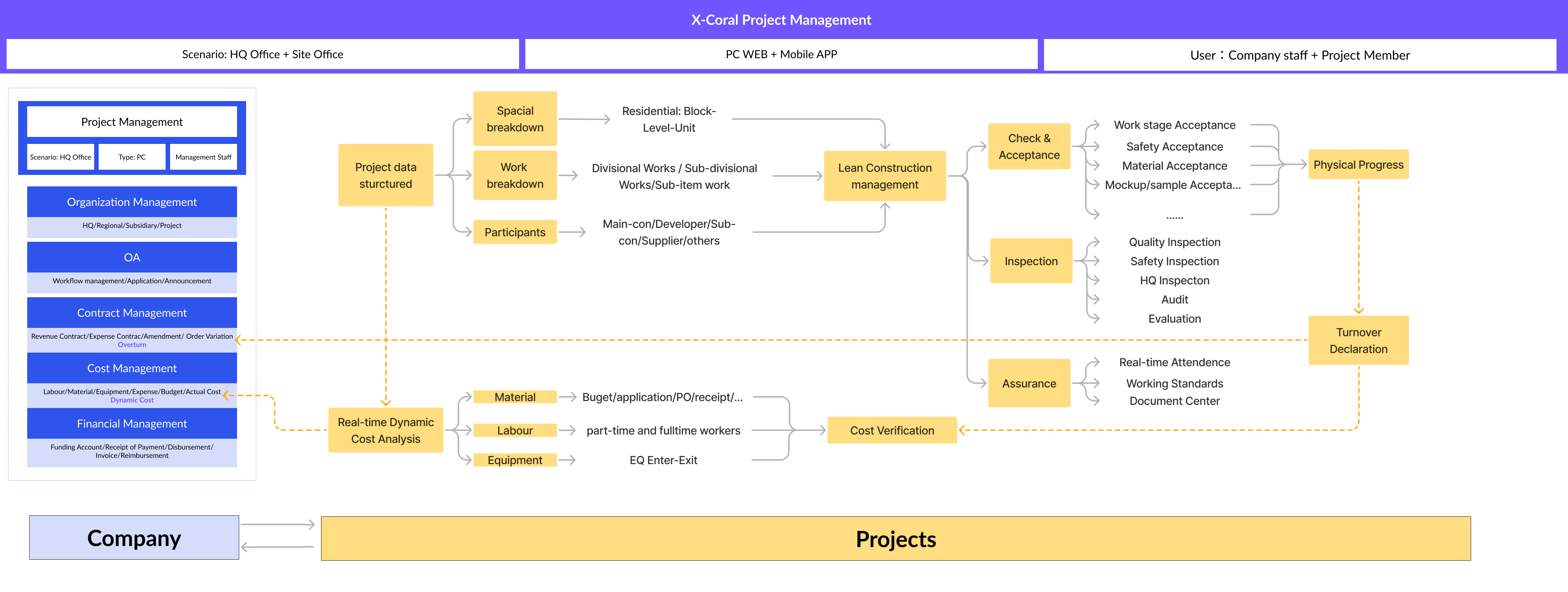

A holistic solution spanning from corporate level to project execution

— X.Safety —

The safety module streamlines safety management with a standard library, PDCA process, and mobile operation, enhancing problem discovery and resolution efficiency, unifying security standards, and ensuring continuous improvement through comprehensive monitoring and root cause analysis.

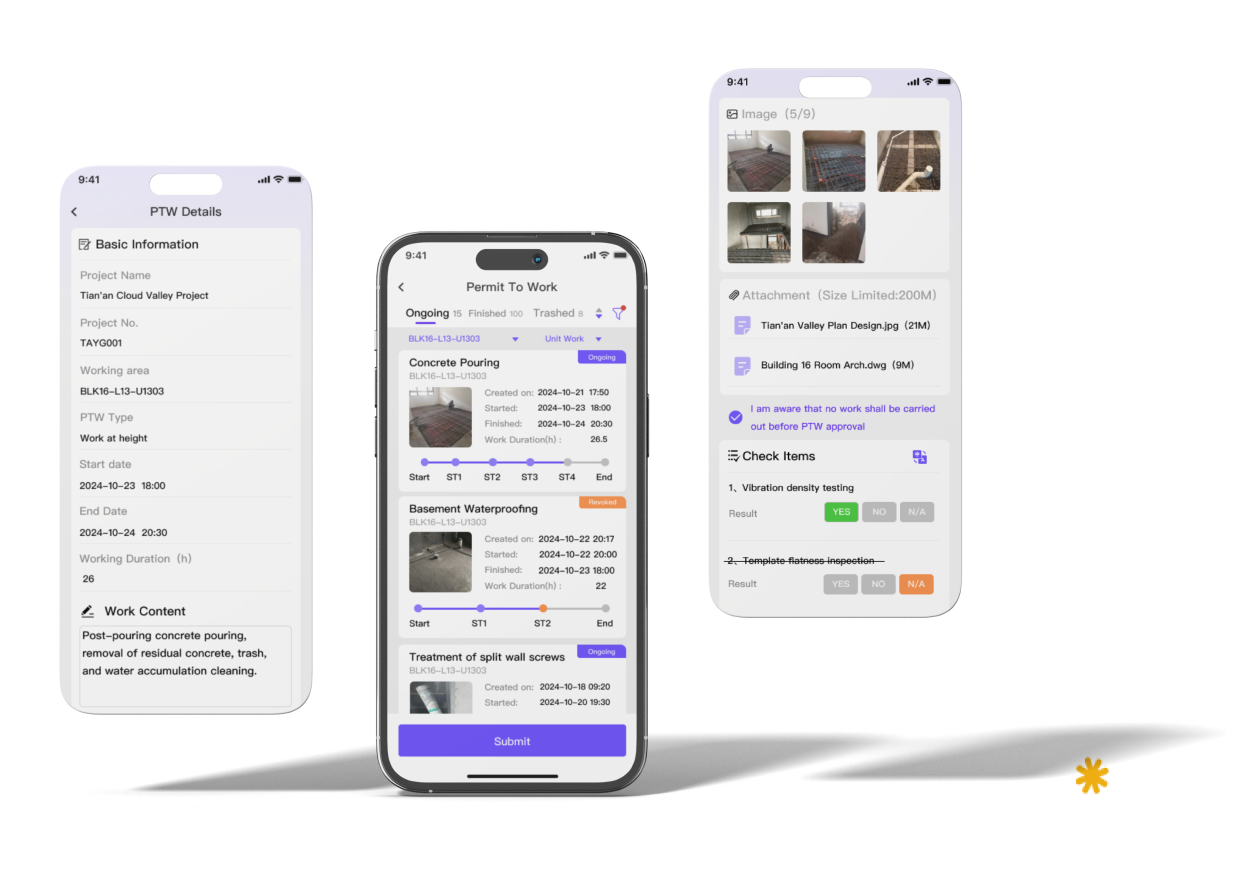

Permit To Work:

Double Guarantee of Compliance and Efficiency

1.Legality supervision:

The safety construction permit function supervises whether construction activities comply with laws and regulations, ensures that all construction procedures are legal, and avoids legal risks caused by illegal operations.

2.Simplified approval process:

Managers can easily track and update construction permit status, simplifying the approval process, improving construction efficiency and reducing construction delays caused by permit issues.

3.Avoidance of legal liability:

Ensure that construction activities are carried out within the legal framework, avoid fines and legal liabilities arising from violations of safety regulations, and protect the rights and interests of projects and enterprises.

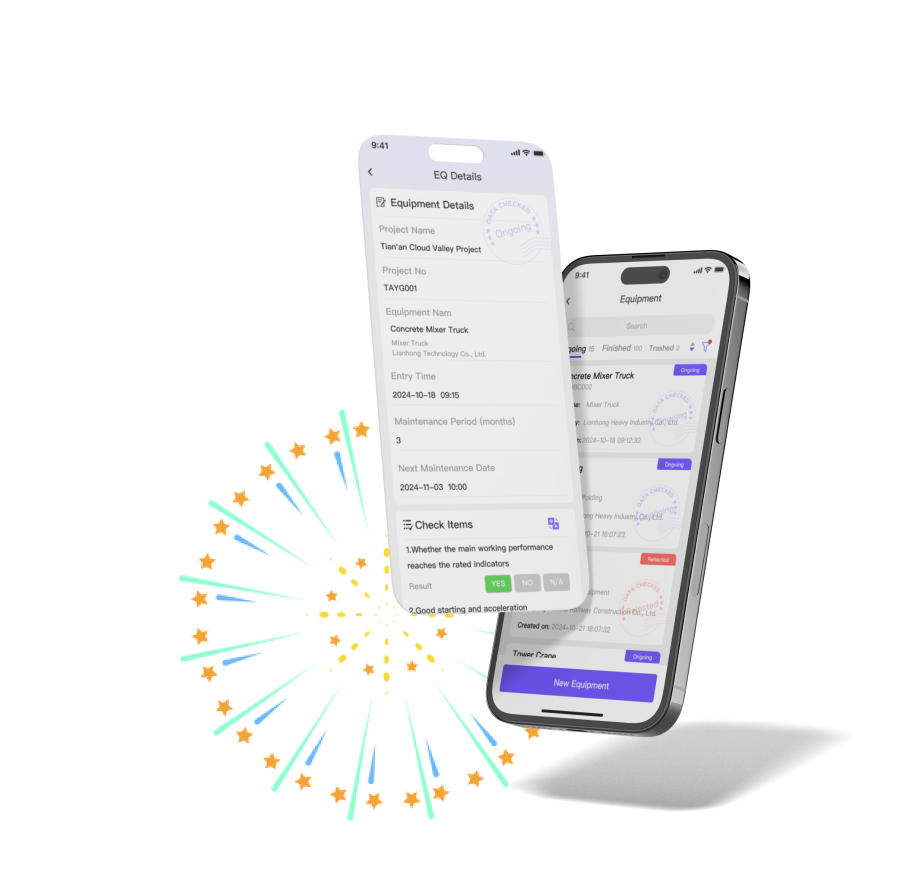

Equipment inspections:

Preventive maintenance to reduce the risk of accidents

1.Safety risk reduction:

Equipment inspection can effectively reduce safety risks during construction, detect and deal with equipment problems in a timely manner, and ensure the safety of personnel and equipment.

2.Preventive maintenance:

Regular inspections help reduce equipment failures, prevent possible accidents, and ensure construction safety.

3.Maintenance record tracking:

Establish detailed equipment maintenance records to provide data support for future maintenance decisions and improve equipment management efficiency.

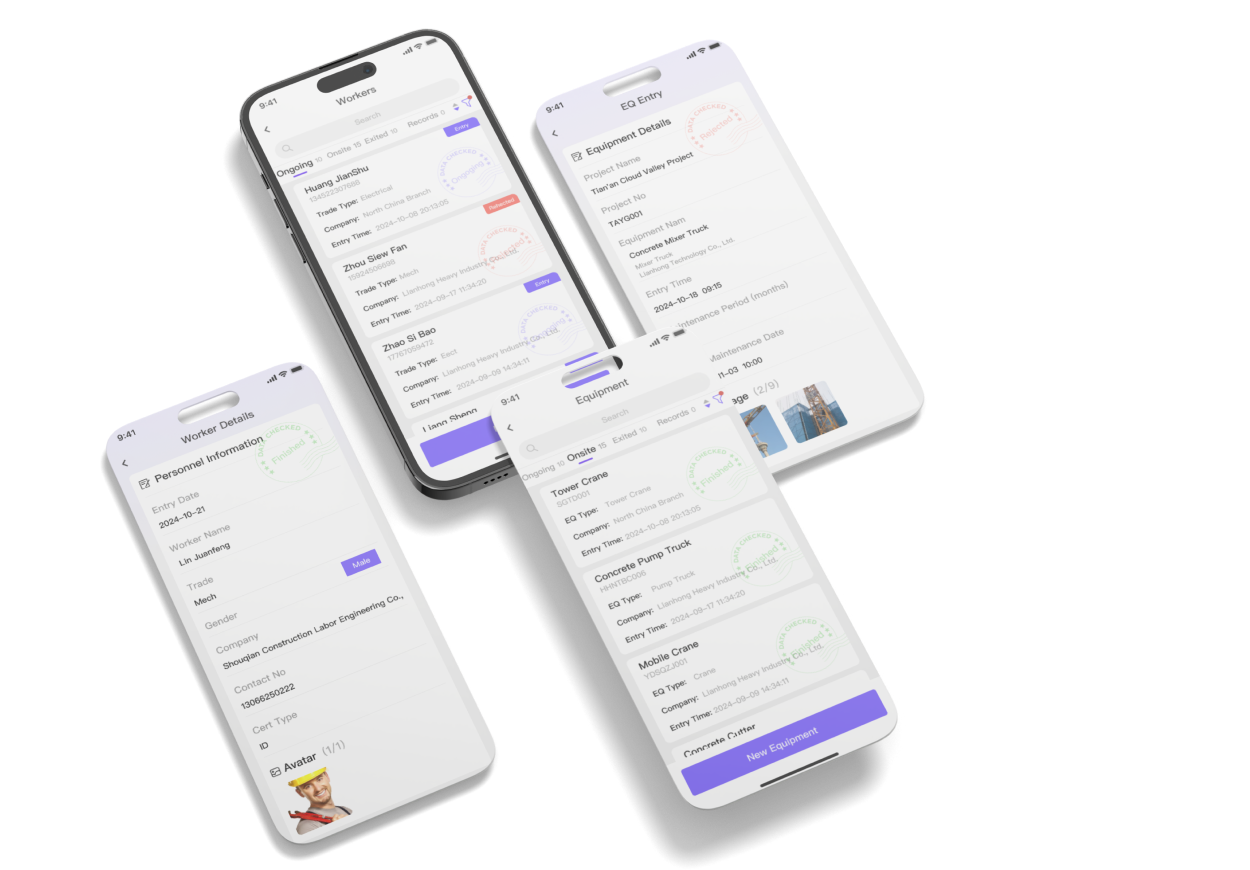

Personnel and Equipment Management:

Enhancing Safety and Efficiency on Construction Sites

1.Equipment Flow Control:

Real-time monitoring of equipment entry and exit to ensure movement and storage according to plans and safety standards, improving turnover rates.

2.Equipment Information Recording:

Detailed recording of equipment ownership, operation time, and maintenance conditions to support equipment management and maintenance.

3.Personnel Tracking and Optimization:

Monitoring personnel entry and exit to ensure valid work permits and safety training, optimizing human resource allocation to improve construction efficiency.

4.Clarification of Safety Responsibilities:

Recording personnel entry and exit, unit affiliation, and contact information to clarify safety responsibilities and promote accountability.

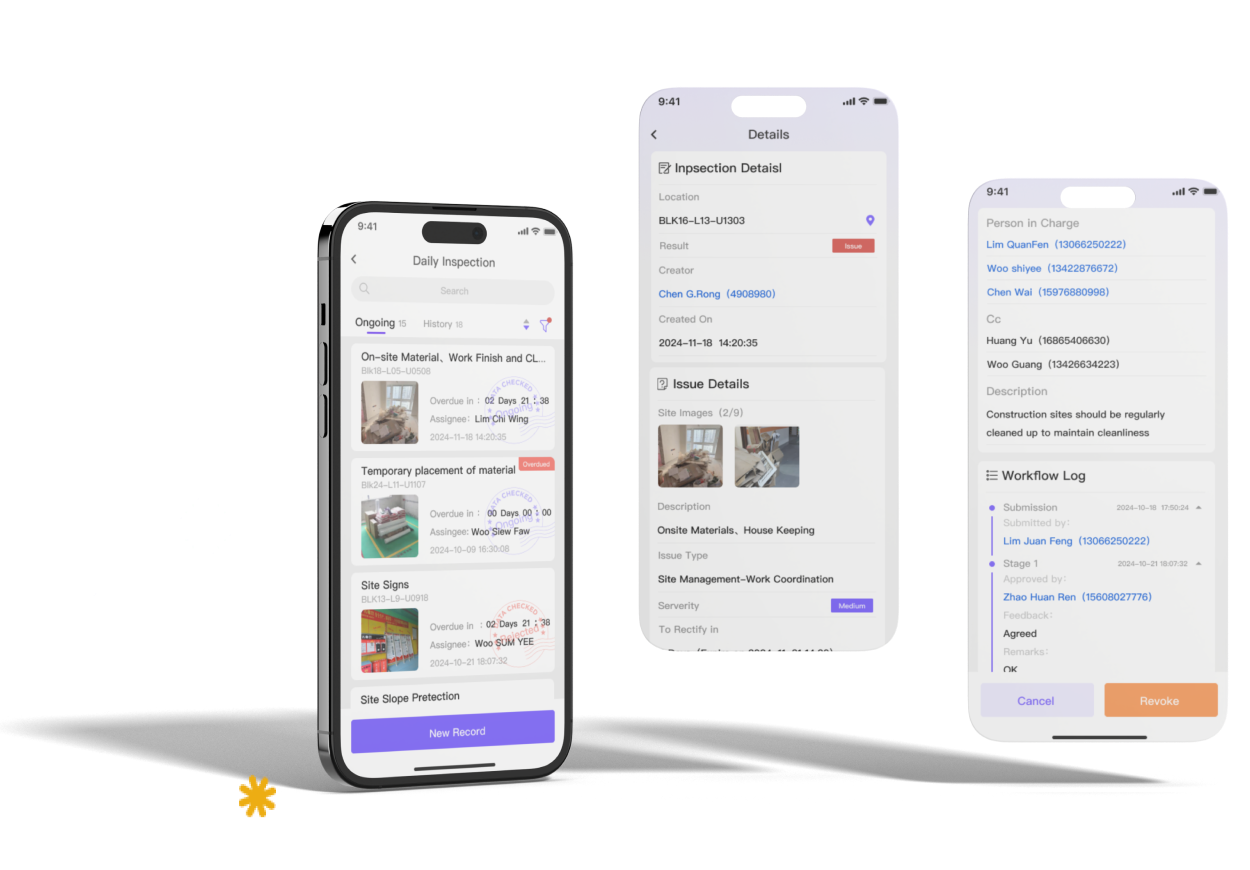

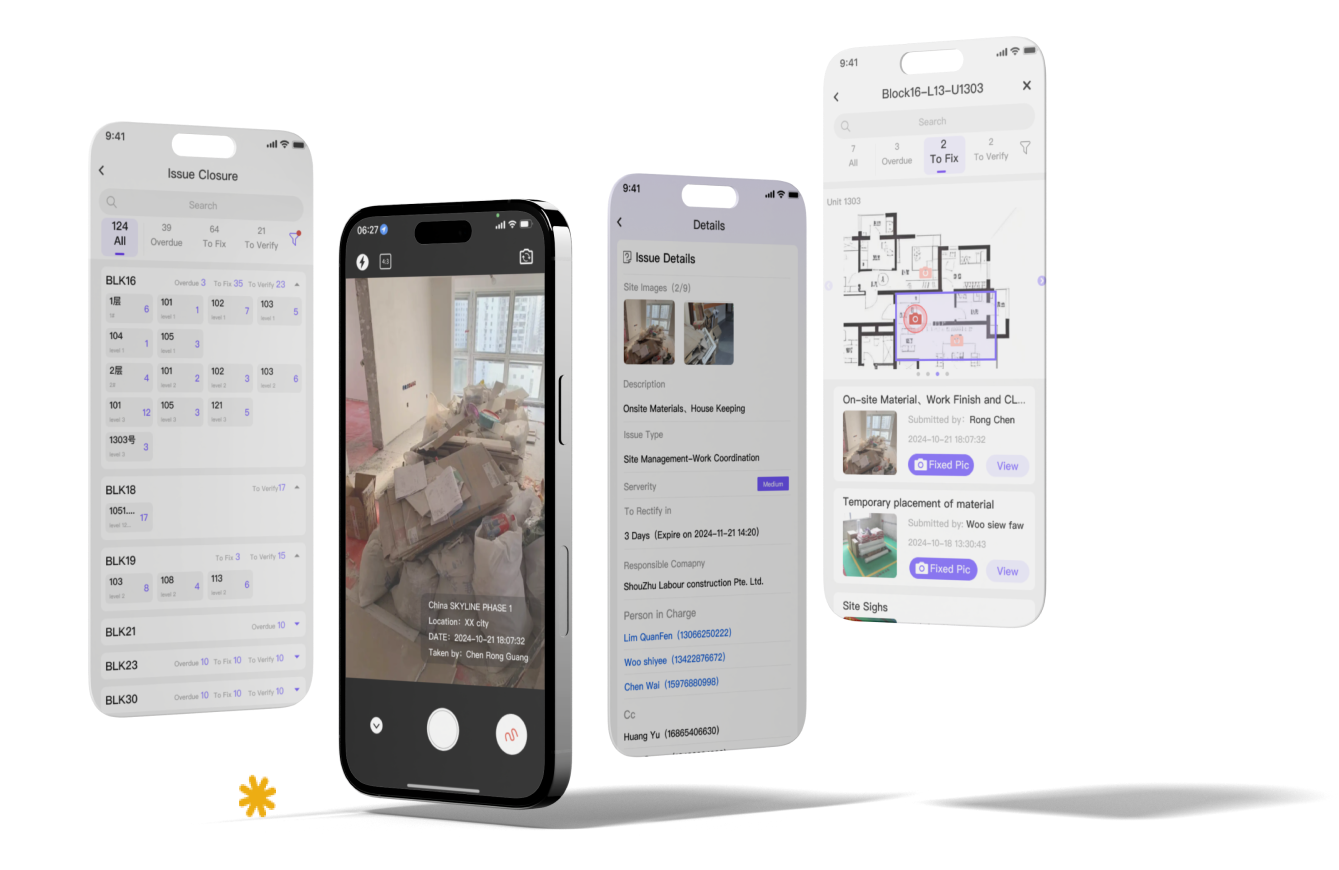

— X.Quality —

The quality management module enhances project quality control digitally. It ensures projects meet established standards and monitors issues and progress in real time. By clearly assigning responsibilities, it ensures tasks have accountable individuals and quality issues are resolved promptly, improving overall project quality and delivery.

Process Acceptance and Visual Progress:

Mobile Office, Visual Engineering Progress

1. Solidify quality control system standards:

Precipitate quality inspection items and judgment standards, and the system automatically pushes inspection content to improve standard implementation capabilities and inspection quality inspection efficiency.

2.Dynamically monitor problem rectification:

Implement a closed-loop control model of quality inspection, quality problem rectification, and quality problem closure to ensure that the responsibility for handling tasks is assigned to the person responsible.

3.Improve collaboration efficiency:

Open the mobile terminal, handle and provide feedback on problems in a timely manner, and improve the collaboration efficiency of problem release and feedback.

Problem closure:

Closed loop on the palm of your hand, problem ends

1.Problem elimination:

Ensure that every quality problem is solved in a timely manner and comprehensively improve the quality of project delivery.

2.Clear responsibilities:

Implement reward and punishment measures to ensure quality meets requirements, and assign responsibilities to individuals.

3.Traceability of quality issues:

Upload supervision and rectification records and rectification results in real time to achieve traceability of quality issues.

Process Acceptance and Visual Progress:

Mobile Office, Visual Engineering Progress

1.Collaborative Operations and User-Friendly Processes:

Supports online collaborative acceptance among multiple roles to ensure consistent quality standards. Tasks can be quickly completed through simple clicks, selections, and photo-taking, streamlining processes and increasing efficiency.

2.Online Monitoring and Data Traceability:

Implements online quality management for construction sites, enhancing management efficiency and transparency. This facilitates real-time monitoring and problem response, with full traceability of acceptance process data.

3.Visual Engineering Progress:

Provides a visual representation of completed processes, offering an intuitive display of engineering progress. This aids in managing real-time project progress and improving decision-making efficiency.

4.Enhanced Transparency and Resource Optimization:

Visual progress charts provide all project stakeholders with clear information on engineering progress, increasing transparency in project management. This supports managers in making quick decisions and optimizing resource allocation.

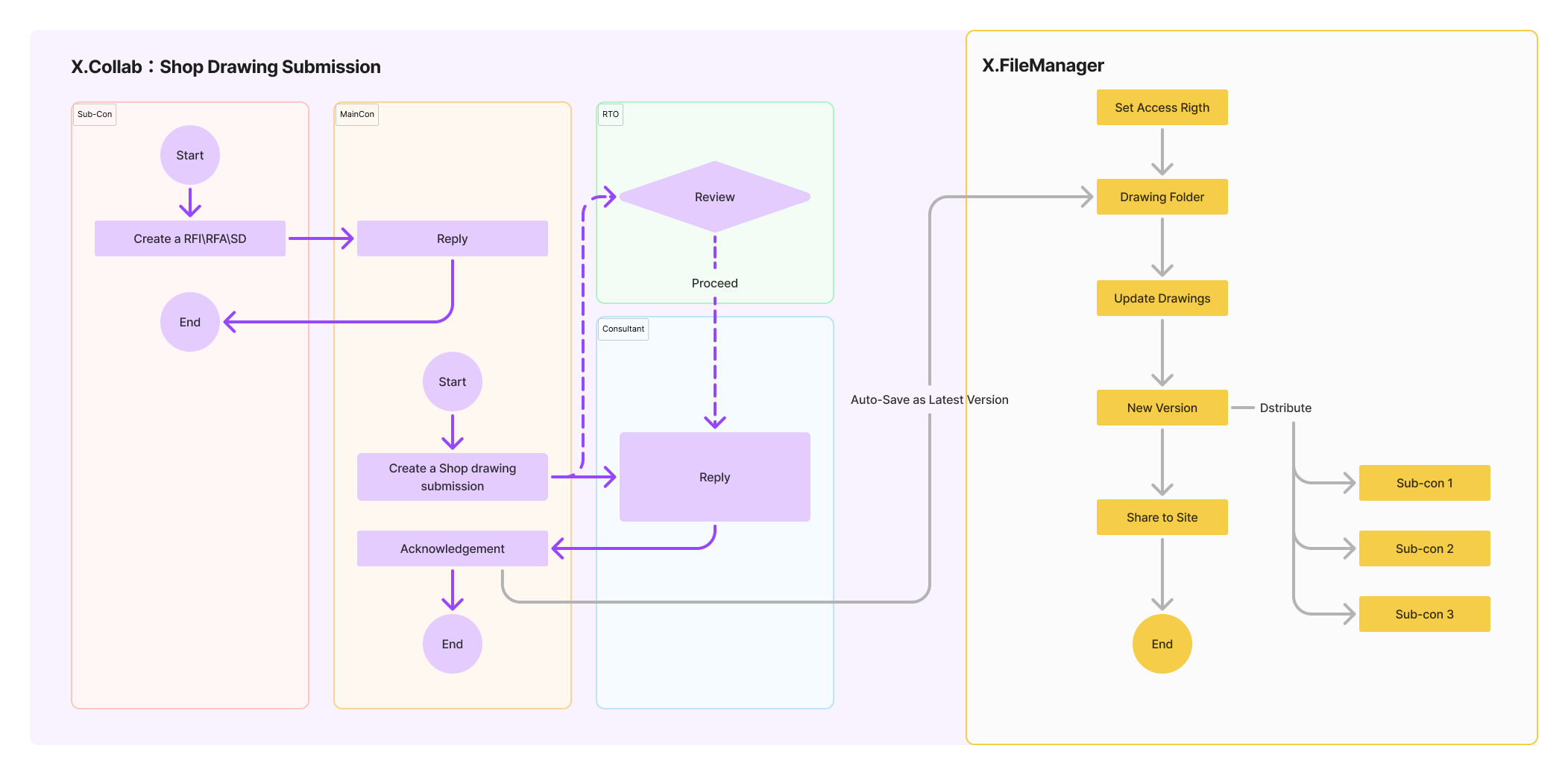

— X.Collab —

Digital project management significantly enhances the efficiency and effectiveness of RFls, RFAs and Shop Drawings by increasing transparency, fostering collaboration, providing data analytics, and adapting flexibly to changes.

Digital Project Collaborative Management:

Enhancing Transparency, Collaboration, Insight, and Flexibility

1.Enhanced Transparency and Accountability

Digital management records detailed information of RFIs and RFAs, providing a clear audit trail that ensures project participants are accountable for their actions and decisions.

2.Improved Collaboration and Communication

Digital platforms support real-time collaboration and communication, with integrated communication tools like instant messaging and comments, enhancing team collaboration efficiency.

3.Data Analytics and Insight

Digital systems collect and analyze RFI and RFA data, helping to identify trends and bottlenecks in the management process, optimizing project workflows.

4.Scalability and Flexibility

Digital processes are easily scalable and adjustable, adapting to changes in project size and complexity, reducing manual operations, and increasing efficiency.

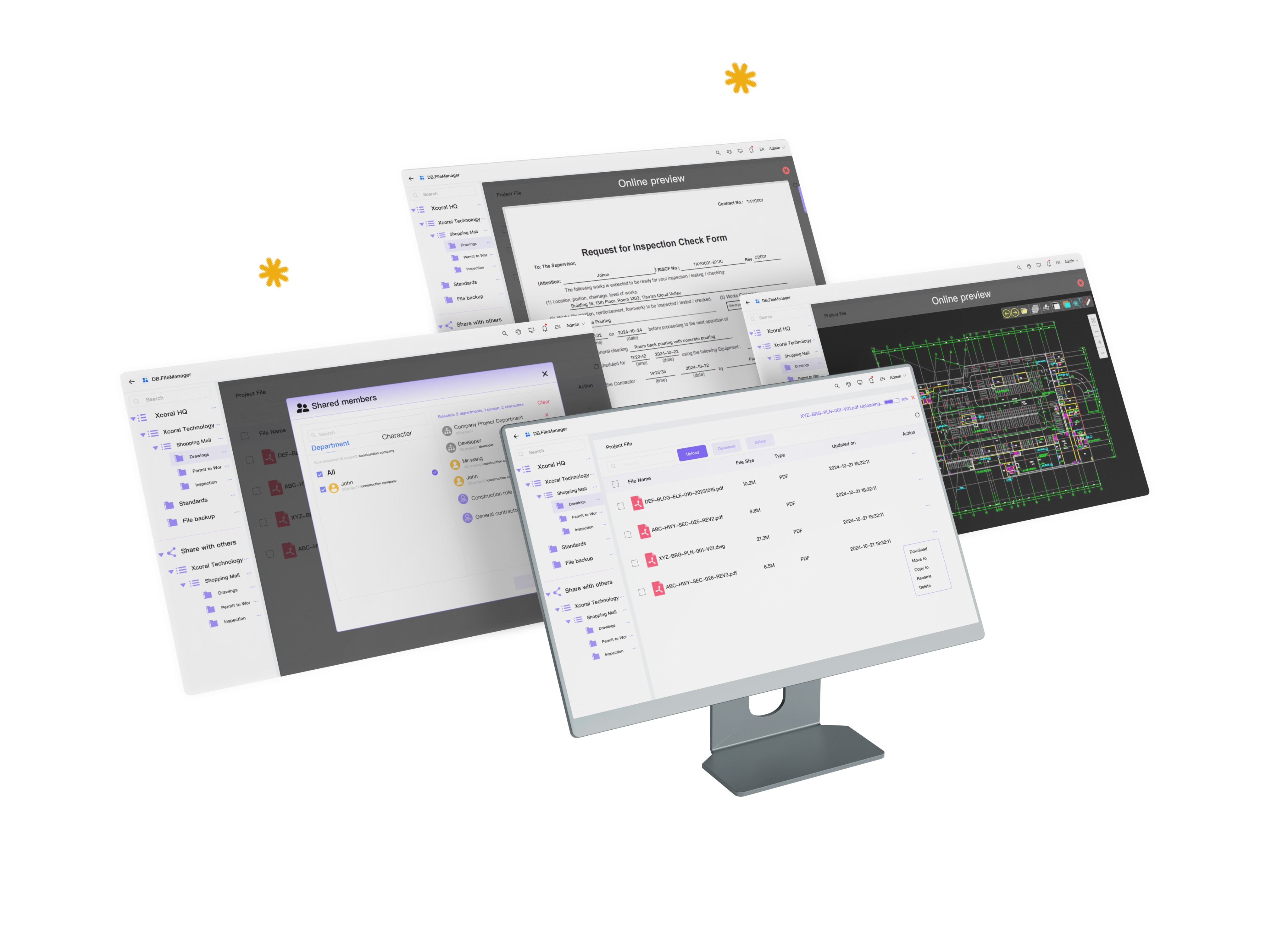

— X.FileManager —

The FileManager offers a secure, efficient, and compliant document management solution. It emphasizes data security with multi-layer encryption, access control, and comprehensive backup. The system ensures document integrity and confidentiality, with traceability and permission management that meet high standards.

File Manager System:

Secure, Efficient, Traceable

1.Itelligent Backup Forms:

Automatically back up critical construction operation documents to ensure rapid data recovery and maintain business continuity.

2.Online Preview and Editing of Drawings:

Provide online preview and editing functions for drawings to improve work efficiency and team collaboration.

3.Data Security Fortress:

Utilize top encryption technology to ensure document storage and transmission security, preventing unauthorized access and data leaks.

4.Refined Permission Management:

Implement refined permission settings to ensure only authorized personnel can access sensitive information, enhancing internal control.

5.Strict Access Control:

Implement identity authentication and role/attribute-based access control to ensure only authorized users can access sensitive data.

— X.DfMA —

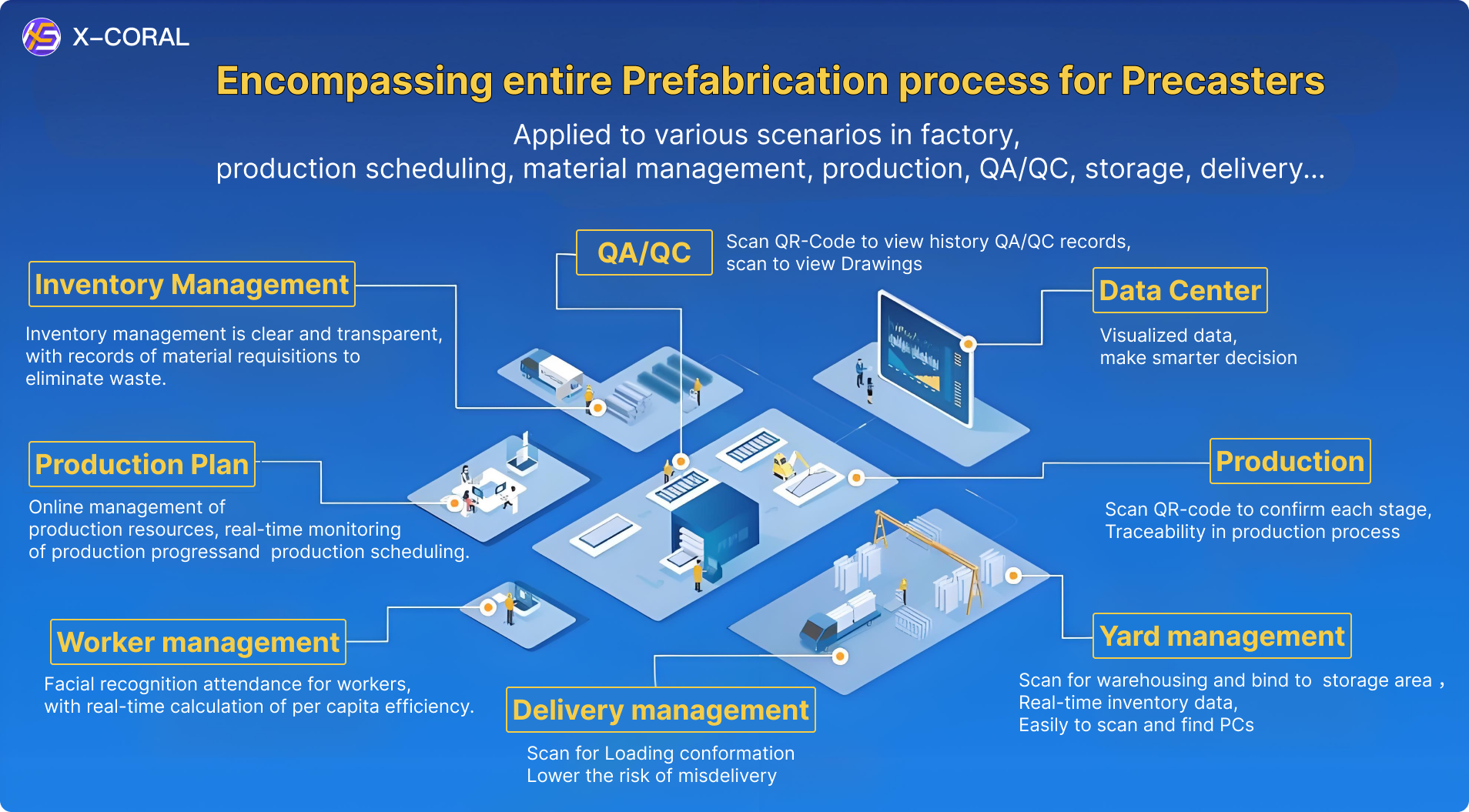

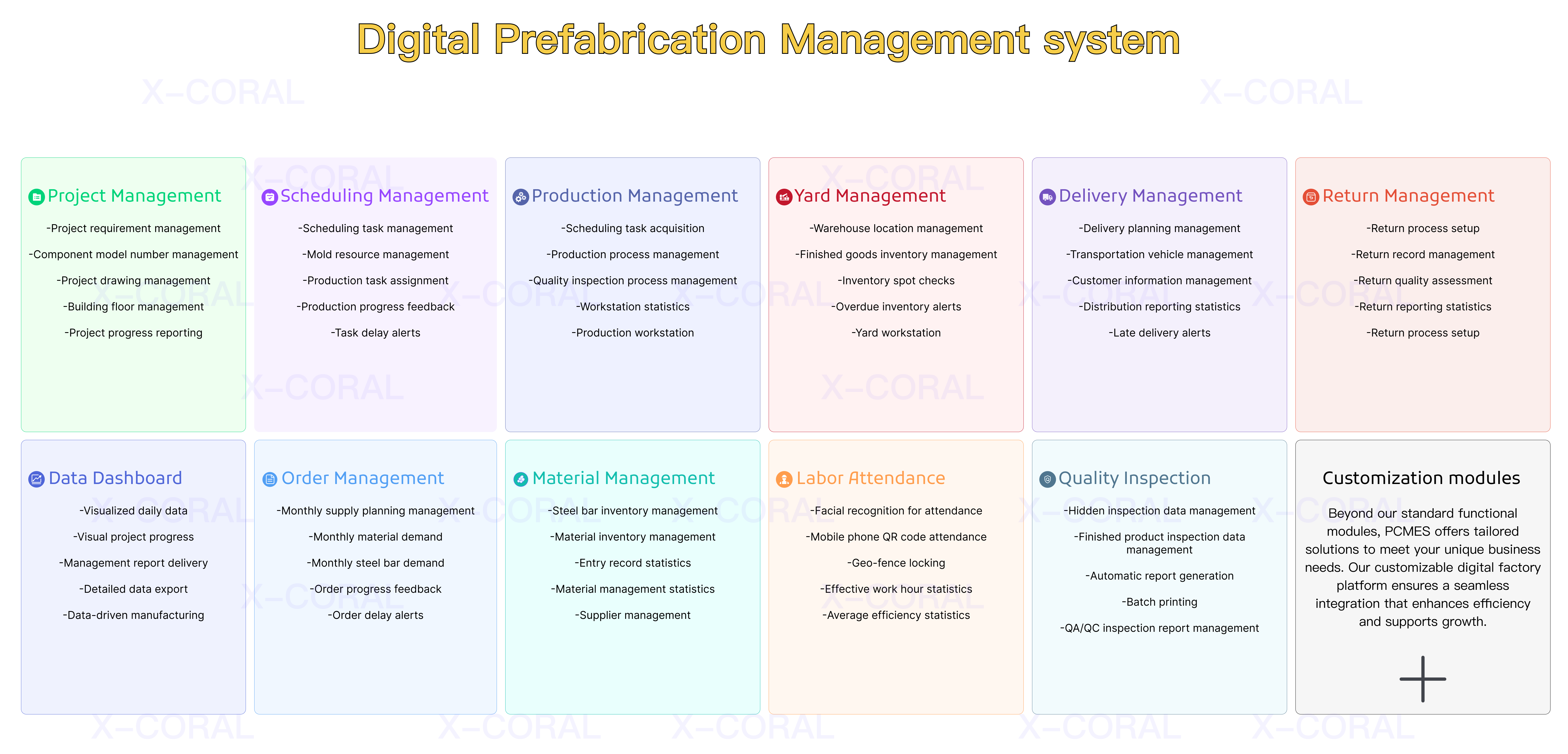

The DfMA system automatically summarizes statistical business reports, supports labor, transportation, project settlement, etc., with mobile priority, real-time data is summarized to the project data dashboard, monitors material consumption, intelligent inventory inventory, and automatic warning line reminders.

PreFab:

Multi-end collaboration, project progress is clear at a glance

1.Mobile Priority:

Most functions are completed on mobile devices, making remote work easy and convenient.

2.Real-time Data Dashboard:

Large screen displays for production lines, yards, and factory data centers provide an intuitive understanding of production progress and inventory status.

3.Material consumption monitoring:

Real-time calculation of material requirements based on plans to assist in precise procurement.

4.Intelligent inventory management:

Scan for entry, intelligent inventory counting, easy to find components.Set work alert lines, and the system automatically sends reminder messages when triggered.

5.Automatic Report Compilation:

One-click download of detailed data, supporting various settlements.

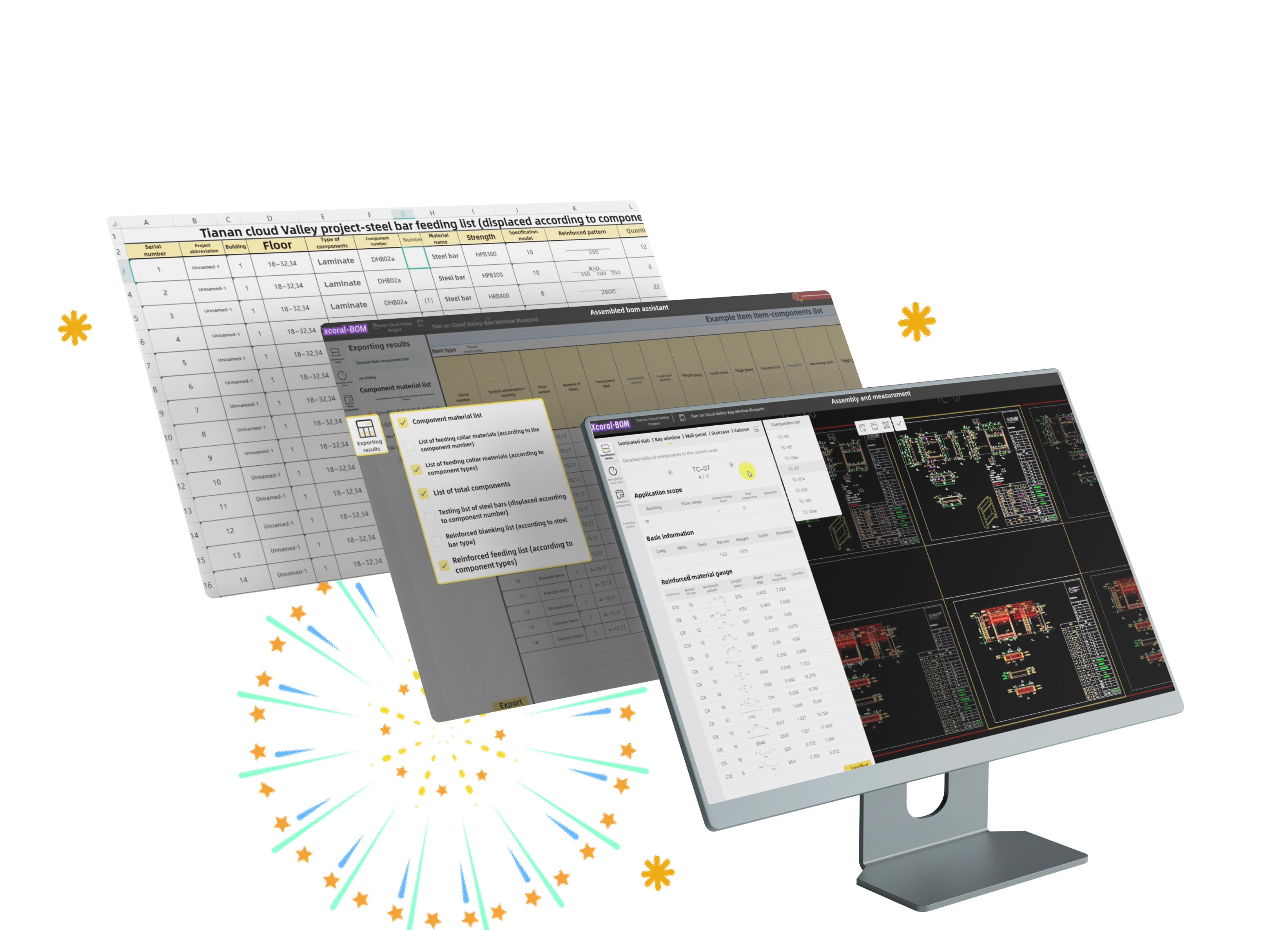

— X.PCbom —

The PCbom software is designed specifically for the production challenges of prefabricated buildings. It can extract BOM tables from DWG and other graphic files with one click, solving the data source problem for digital production and significantly improving design and production efficiency. The software supports intelligent recognition of drawings, rapid calculation, with an accuracy rate of up to 98%, making online operations easy and fast.

PCbom Software:

Efficient and Intelligent Detailed Drawing Recognition and Data Management for Building Components

1.One-Click Recognition and Rapid Quantification:

The software enables one-click recognition of building component details, quickly obtaining project quantity information with an accuracy rate of 98%.

2.Smooth Operation Experience:

Supports import of various file formats up to 300MB, ensuring lag-free operation and a smooth zooming experience.

3.Intelligent Verification and Conflict Detection: ess:

Automatically extracts plan information, intelligently verifies and marks conflicts between plan and detail drawings, enhancing project quantification efficiency.

4.Online Project Quantification and One-Click Export:

Supports online project quantification, one-click export of component BOM data, facilitating factory production integration.

5.Data Support and Rapid Quotation: ntrol:

Imports project source data to automatically generate material cost and quotation lists, accelerating the business process.

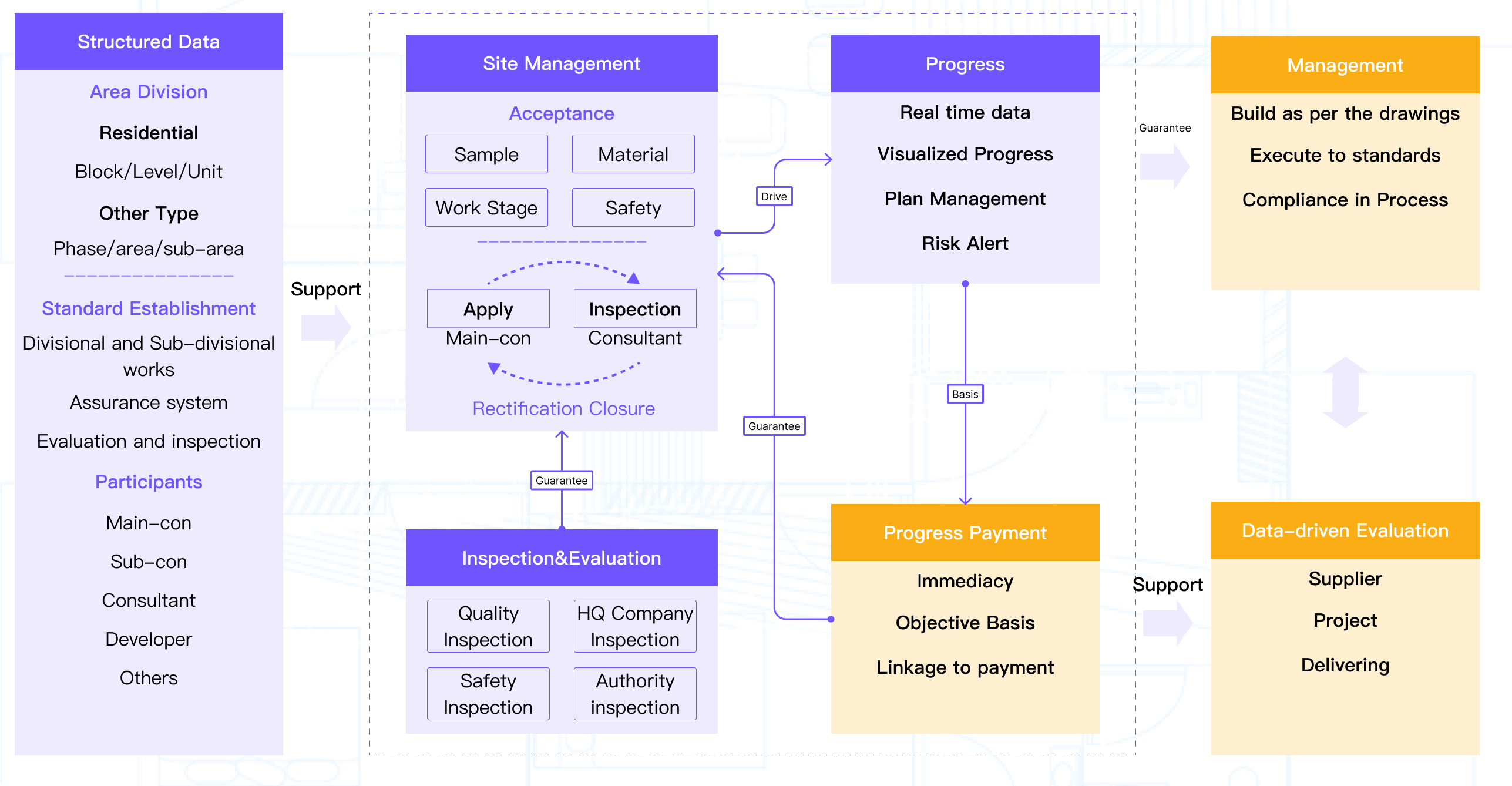

— Solutions —

Solution for Main Contractor

The essence of covering the entire lifecycle of construction projects and achieving digital control over quality, safety, and progress lies in bridging the information gap between the office and the construction site. This ensures that management and decision-making are based on authentic, real-time, first-hand information from the field.

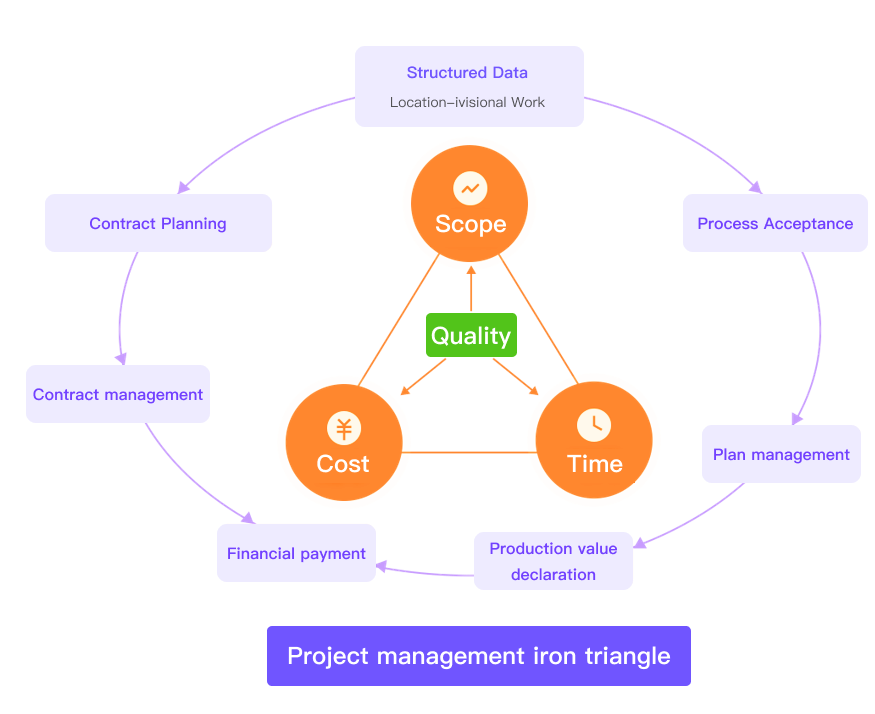

The Iron Triangle of Project Management

For general contractors in construction, the fundamental competitive edge lies in their ability to complete engineering projects with qualified quality, within the scope and timeframe specified by the owner, and at a controllable cost.

Building on the iron triangle of project management—namely "cost," "time," and "quality"—the key to sustaining competitive advantage is how to enhance competitiveness and achieve cost control through digitalization.

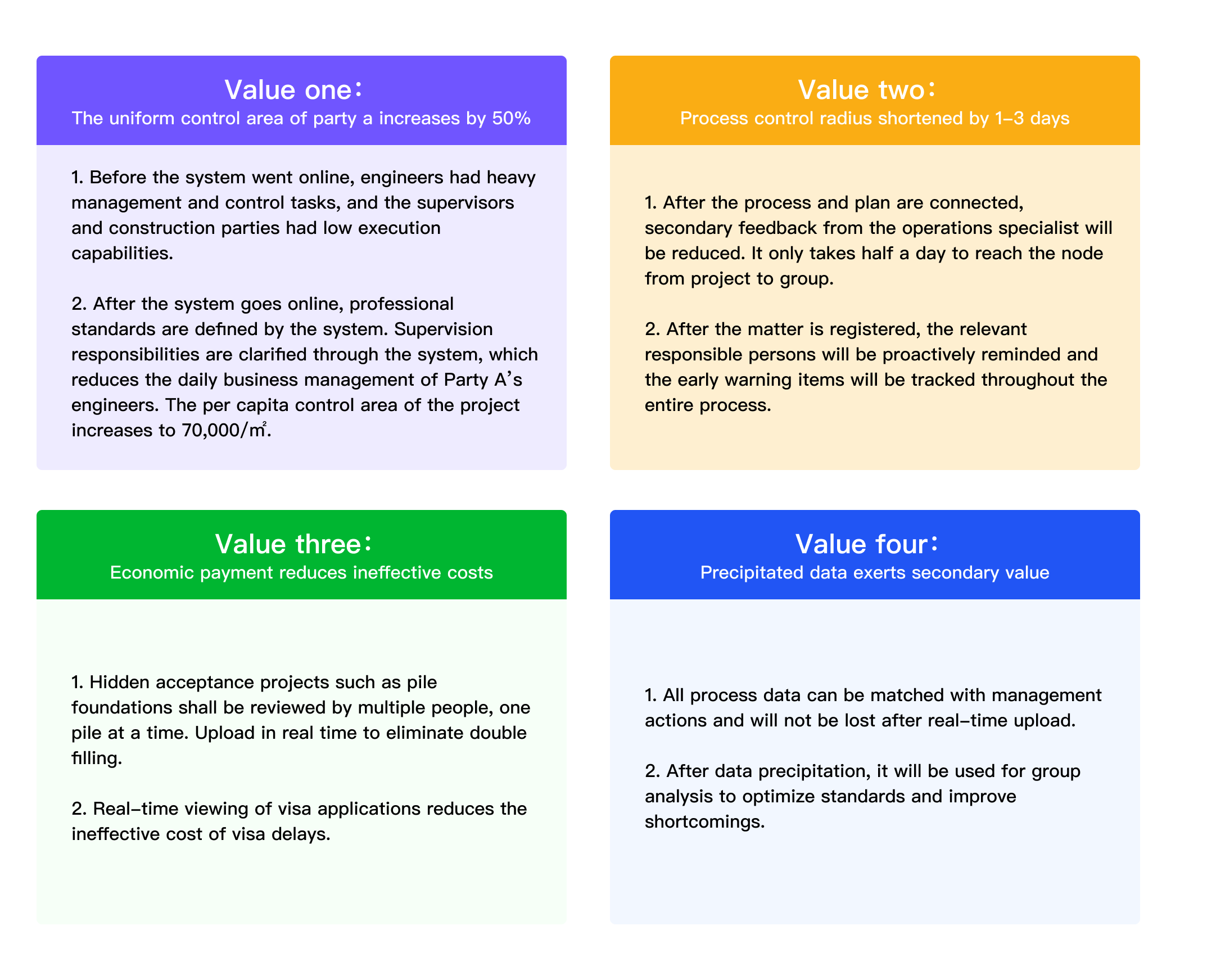

The Application Value

For The business value that digital engineering management brings to the entire process of project management is evident, mainly reflected in four major aspects.

Comprehensive product solutions

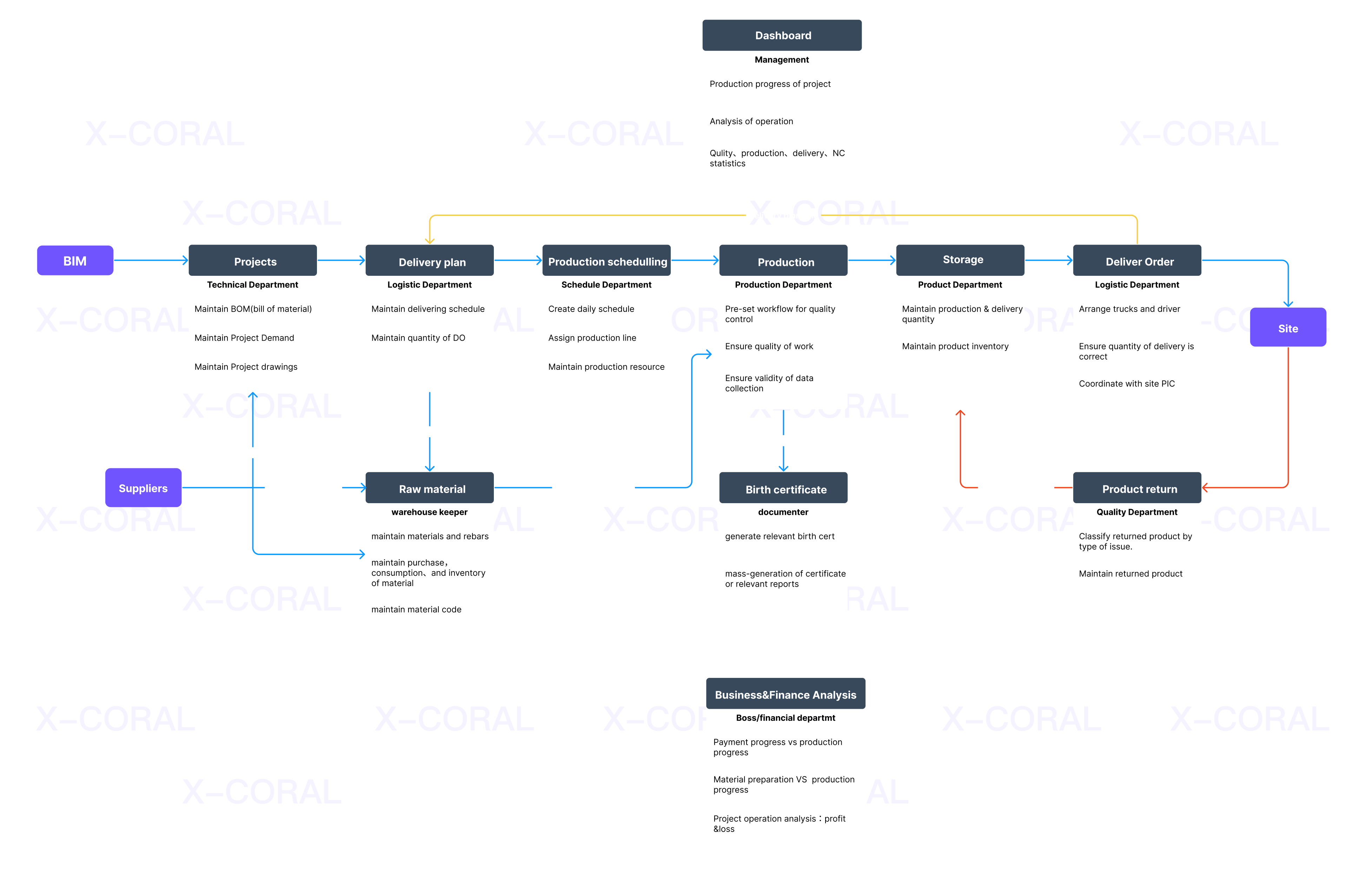

Digital Factory Solution

The digital factory utilizes the DB.PreFab system to achieve real-time monitoring and management of the production process, optimize production planning, coordinate the connection between processes, reduce waiting and downtime, maximize the utilization of equipment and personnel, thereby improving production efficiency, reducing costs, enhancing quality, and achieving informatized management.

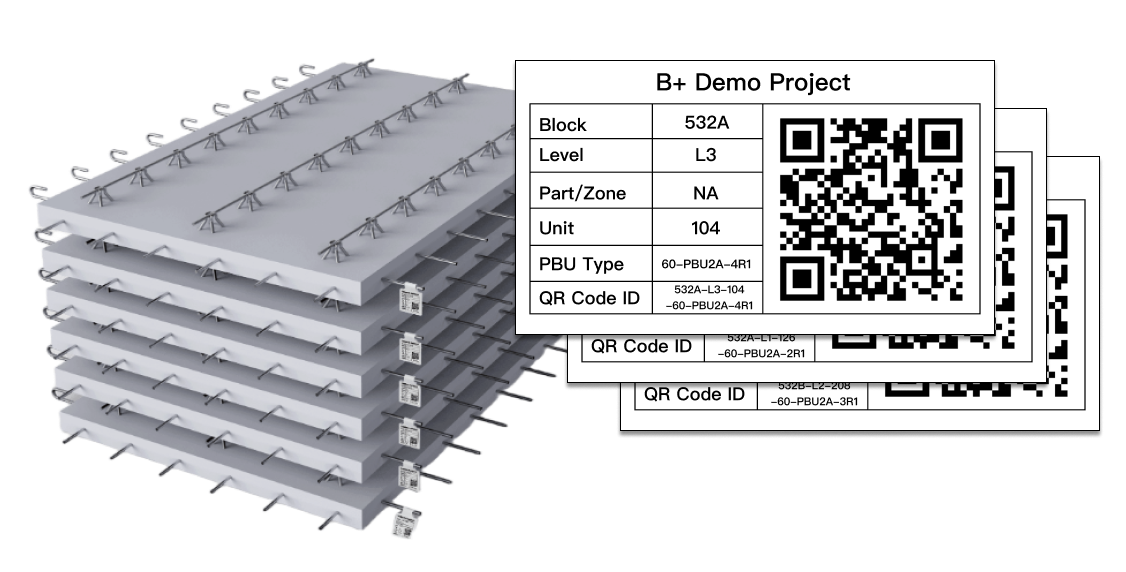

Smart Component Tracking:

One Code, All Information at Hand

By equipping construction components with unique QR codes, we enable instant access to and management of construction information. With a simple scan using a mobile app, the construction team can view component specifications, design drawings, and production records, enhancing transparency and efficiency in the construction process.

Factory insight data:

Real-time control, all in the palm of your hand

Real-time monitoring of casting production capacity, inventory intake and shipment volumes, and stock status ensures production efficiency and smooth supply chain operations; tracking project and production progress, optimizing inventory management, and adjusting plans in a timely manner achieve comprehensive transparency and efficient management of factory operations.

欢迎随时联系我们:

XcoralSales@gmail.com